Before simulation, validation of new systems under test (complete vehicles, ADAS command law, headlights, etc.) were only physical tests, which means that we deployed several versions of prototypes on a track in order to make sure that the behavior is what was expected.

The aim of those physical tests is to improve the quality and performances of the systems by realizing various driving situations with specific conditions. To do so, each project team wants to optimize costs and minimize the delay of the development phase and try to accelerate tests and validation, while guaranteeing the safety of employees and users.

On the other hand, simulation has brought new challenges and possibilities since the 90s. Simulation helps car manufacturers, OEMs, research centers, and others to develop and accelerate digital mobility systems and models by diversifying the possible driving situations (more actors, different roads, etc.). To increase the speed of testing and validation campaigns, and also employees safety, simulation enables the use of driving simulators. It also helps the creation of prototypes in each conception step (from MiL to ViL) to improve performances and quality of systems including better technological and/or ergonomic choices earlier in the project.

For more than 30 years, AVSimulation teams have been developing a simulation tool to address these concerns. Thanks to SCANeR, you can replicate digital twins of your SUTs and benefit from a rich and representative environment to validate them iteratively in open and/or closed loops in many different fields of the automotive industry.

For instance, regarding the development of a new headlight system, the development cycles are no longer based on seasons, as simulation enables users to have control over the environment. If you need to perform night driving (or rain driving), you don’t have to wait anymore for specific weather conditions; headlight teams can test, validate and tune their systems during the day-time! Efficiency, glare, or discomfort can be measured within the simulation (and/or in a driving simulator). It also allows the user to test emergency or complex situations, avoiding any risks and measuring reactions of the tester on an open road.

Last but not least, development of prototypes, which represents a high investment (regarding the low quantity that are created) of a project, can be reduced thanks to simulation. Regarding a headlight project, we measure a reduction of 3 to 5 mock-ups thanks to the Headlight pack for SCANeR, and only the last one is used to validate the assembly tools and performances. This directly affects the ROI of a project, with a cost reduction from 600 thousand euros to 1 million euros.

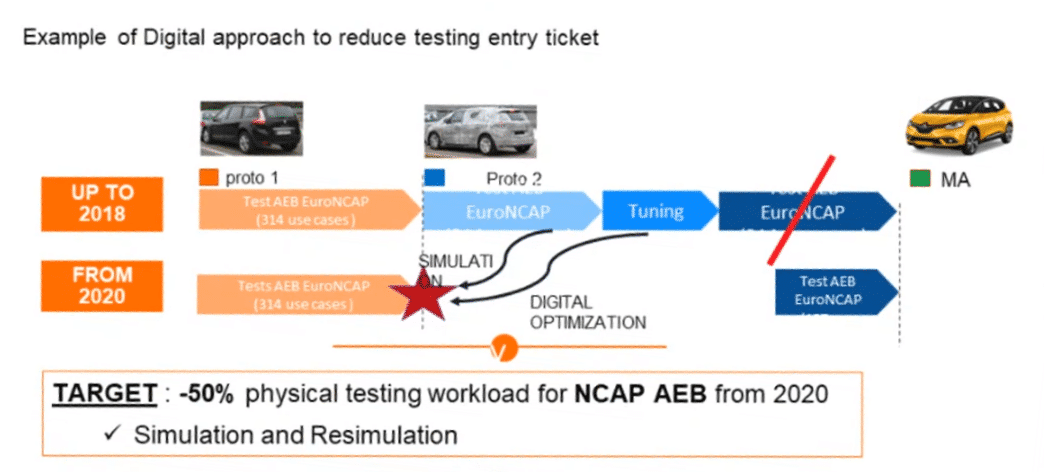

This is also true for other systems composing a vehicle. For instance, ADAS tests performed during a NCAP campaign can also be optimized. The picture below shows Renault’s experience using SCANeR and its NCAP & Regulation pack. When simulation is used, detection of intermediate issues and tuning of the system is done before the deployment of a prototype, which can lead to a first successful on-track test (knowing that only the complete EuroNCAP campaign cost around 350 k€).

The testing regulations have also changed over the last few years. Good examples are the SOTIF scenarios that requires “unknown scenarios”. A way to discover such “unknown scenarios” can be running millions of scenarios in parallel and changing values of the different parameters of the test. The Massive Simulation pack for SCANeR helps to deploy cloud architecture for SCANeR. Cloud architecture enables the use of a command line version of SCANeR, which enables use with minimal hardware configuration and also fast execution of SCANeR scenarios in parallel in order to test a wide range of values for each parameter.

It has been mathematically proven [cf. https://www.rand.org/content/dam/rand/pubs/research_reports/RR1400/RR1478/RAND_RR1478.pdf] that for a high autonomy level you can’t perform a physical test for every situation. A way to cover the maximum amount of situations is to let the system drive millions, or billions of kilometers which is realizable thanks to a massive simulation platform.

Nevertheless, simulation will never be as true as real tests, regardless of the richness of a digital environment. We still need to have an actual physical test of a full, or partial, system due to the needs that security and reliability entail.

Simulation and real tests are complementary!

We have to keep in mind that simulation offers different levels of description for functional or physical instances. That means that simulation does what we expect from it; physical or optical calculations are based on the description of the materials.

But some physical properties, material descriptions, and/or some complex situations of reality cannot be simulated all together, or cannot be implemented due to randomness or complexity of the representation (e.g., multiple effects of a snow storm on the grip, the visibility, water accumulation, etc.)

Beyond the test phase of a product, simulation needs to have physical tests in order to correlate the truthfulness of the models implemented. Indeed, the only way to digitalize a physical law is to confront result from simulation to actual proving ground tests to make sure the model-based environment is correct and reliable.

One last topic that we have not yet mentioned are the new challenges which autonomous vehicles bring. For the next several years, the automotive industry has to ensure the digital continuity between software, models and vehicles deployed on the road. Vehicle-In-the-Loop projects lead by AVSimulation for few years now are examples of how AVSimulation’s team face these new challenges.

For instance, AVSimulation and UTAC deploys a full car, identical to its digital twin in SCANeR. This was used to test and validate an ADAS command law; the idea was to lure the sensors of the car with virtual obstacles (pedestrians, road infrastructure, etc.). The on-track car reacts relative to what the sensors virtually detected. It allows to test more complex use-case with more actors, longer driving time, etc., and ensures the repeatability and the reproducibility of theses complex situations.

| Such projects illustrate well the complementary strength between simulation and on-track tests. Simulation is a new tool that helps to accelerate test campaigns and offers more flexibility during the development and tuning phase. The results on the project are a reduction of the costs and the capacity to simulate known and unknown situations. However, we have to keep in mind that without proving ground tests, simulation cannot be consistent, and that the industry will always require actual tests (either to test and validate their systems or to validate a modeling of a physical law). |

Written by Ludovic Pfeffer.

If you would like to have more information and be contacted by one of our sales representatives, contact us.